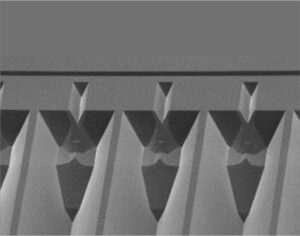

MEMS Micromachining

Example of precision micromachined nozzles by KOH etching

Micromachining is the structuring of silicon and glass by means of lithography, etching and deposition techniques. Micromachining enables the micrometer precise production of large volumes of very small devices, which can be used for a variety of applications.

MEMS Cantilevers

MEMS Cantilevers are beams, attached on one side and free to move on the other side. They are used for a variety of applications including sensing and material research based on AFM or tunneling currents. When they are fabricated in MEMS they are known as microcantilevers.

A cantilever sensors or cantilever biosensor are usually coated with a thin layer, for example a metal or an active biochemical layer (functionalization). The bending of the cantilever is then measured, for example, by piezoresistors or optical reflectance.

LioniX International produces cantilevers from low stress silicon nitride, silicon (SOI) or silicon oxide, which can be coated with a variety of materials.

Other micromachining technology

Lionix International uses several micromachining technologies, such as:

- Anisotropic wet etching of silicon

- Dry etching of silicon (DRIE)

- Dry etching of Fused Silica

- Isotropic wet etching of borosilicate glass and fused silica

- Wafer bonding

- LPCVD of Silicon Nitride

Examples of micromachined chips we have made are:

- Probe tips

- TEM grids

- Groove plates

- OEM parts for a mass spectrometer

- Heated TEM stage