Minimizing coupling losses: a multi-dimensional approach with silicon nitride waveguide tapers

Picture yourself as a young integrated photonics researcher. You did your homework on photonic integrated circuit (PIC) platforms and picked your favourite for your application. You designed a great PIC and picked a fantastic foundry to have it fabricated. You waited for months for it to be delivered. You finally have it in the lab. You set it up on your test bench, and as soon as you try to get light into and out of it, your enthusiasm dissipates along with the signal intensity. You spend the next month figuring out the optimal alignment, and even then, the losses are higher than you expected. Why?

Strange as it may sound, designing PICs with little consideration for its interfaces used to be the most common pitfall of working with PICs. Thankfully, the field has matured enough that fewer and fewer engineers are thinking about PICs in the abstract. The interface between the PIC and the external world is essential to its performance, and it has been argued that the design of the interface is more important than the circuit itself. The design of these interfaces is often referred to as hybrid or heterogenous integration—a vaguely-defined set of methods which all attempt to get photonic signals into and out of the PIC. Hybrid integration generally refers to planar, 2D approaches, where the components are laid out next to each other. This leaves more space for other necessities, like heat management, to be implemented. Among hybrid integration methods, edge-to-edge coupling, where the light enters and exits the PIC through the sides, remains king. From a production and design standpoint, it is the easiest to implement and control.

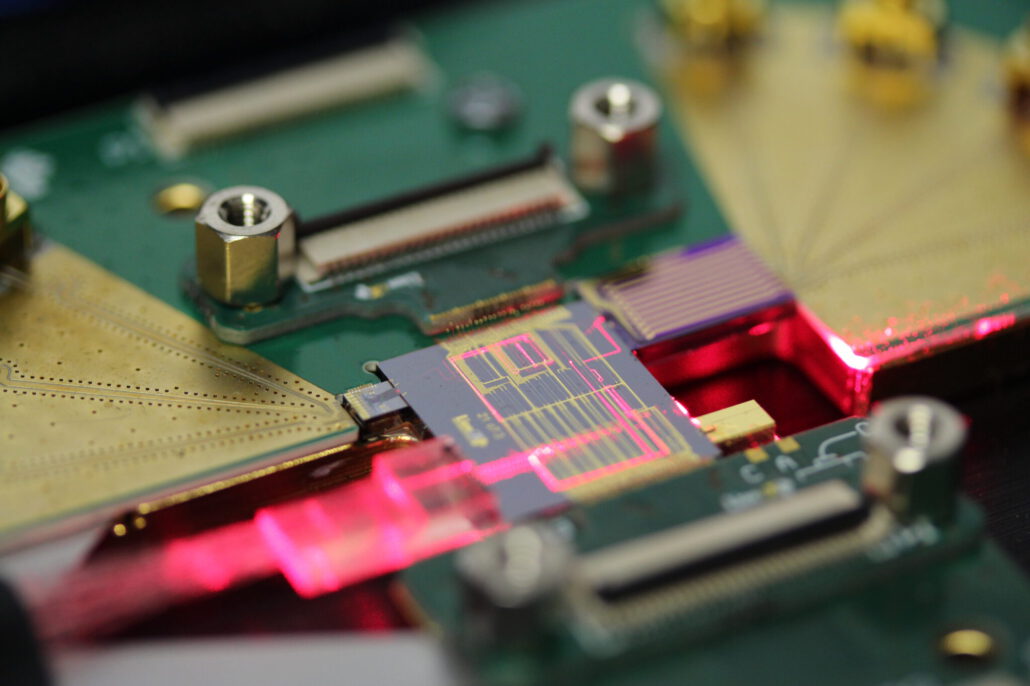

Figure 1: A photonic beamformer with three PICs, a light source, and a fiber output, all edge-to-edge coupled.

How to increase signal intensity in a PIC (without using stadium floodlights)

The most important parameter of a photonic integration method is how well it maintains signal intensity. Signal losses between a PIC and other optical components add up with the propagation losses inside the PIC to attenuate the overall power one can get out of a photonic device. The prime benefit of silicon nitride (SiN) as a PIC waveguide platform is that it is a low loss platform for a wide spectrum of wavelengths. Silicon nitride waveguides have such low propagation loss that, when compared to their coupling losses, different orders of magnitude have to be used. Given its ubiquity, several strategies have been devised to reduce these losses in edge-to-edge coupling. A common strategy involves gradually adjusting the dimensions of the waveguide core,so that the diameter of the light beam can be shaped to better fit a different waveguide. This approach has a few names: spot size converters, waveguide tapers, mode field adapters, Lightwave Slip ‘N Slide. The idea is the same: match the different waveguides as closely as possible, whether to an optical fibre, a photodetector, or a different PIC.

Horizontal and vertical waveguide tapering

When aligning PICs with one another, tapering waveguides on both PICs may be the most practical way to minimize losses across the interface, but that requires precise engineering and fabrication on both platforms, which is not always possible. From a production point of view, the ideal case would be to have all waveguide tapers integrated on one platform, and all other PICs and fibres are placed around it. Integrating other optical functions besides the tapers lets the central PIC reduce coupling losses for the complete device while carrying out its designed role. Due to the low losses of SiN and its passive nature, using it as a routing component is pragmatic. Hence, it is exceedingly important that coupling losses are minimized across SiN.

Tapering is typically done by adjusting the width of the waveguide core. This is a good start, but why work on one dimension when you can work in two? TriPleX® silicon nitride employs two waveguide core layers. Besides the minimal losses this approach allows, it also lets designers to create vertical tapers. The depth of one waveguide core can be adjusted continuously, providing an extra dimension of control.

Figure 2: Artist’s representation of the depth tapering possible on TriPleX(®) silicon nitride PICs.

This gives our TriPleX® PICs an extra edge: by combining horizontal and vertical tapers, the light field can be accurately matched to fibres, light sources, and other PICs. This alleviates the signal loss bottleneck at the interfaces. By dropping our edge losses as low as 0.3 dB, our low propagation losses at 0.1 dB/cm can really matter for the overall device performance. It also allows other PIC platforms to be fabricated at the optimal waveguide stack for their unique functions, like light generation. It equips SiN PICs for acting as central routing chip which guide light between light sources, high speed modulators, photodetectors, and optical fibers, without worrying about how many chip-to-chip interfaces that adds up to. In our beamforming applications (Figure 1), where signal fidelity is crucial, all four of these components are integrated around our TriPleX® PIC. It is also one of the many tools we use for our high Q external cavity tunable lasers, such that its output power can reach 20 dBm at 1550nm with 100 nm tunability. The benefits carry over to the visible light spectrum, where low coupling losses allow our chips to act as light engines for AR applications, as in our work for project MatEl.

Your PIC is more than a chip

Now, step back into the shoes of the young integrated photonics researcher. Taking overall device design into account at the circuit design stage let you take a holistic approach towards innovating in your application field. You remember fondly the time you spent reading a blog on the LioniX International website about the importance of edge-to-edge coupling and the different approaches you could choose from. In a few years’ time, that knowledge will enable you to design the world’s first integrated photonic device which can simultaneously operate at 50 W and solve world hunger. That device is in every laptop, smartphone, and spatula across the solar system. Taylor Swift writes a song about you, and you like it.

Our custom design, fabrication, and assembly experts are always happy to answer your questions! Get in touch via our contact form.

LioniX International’s marketing & communications director, Sadoon graduated with an MSc in Nanotechnology from the University of Twente. When not at an exhibition or meeting industry partners, he can be seen around the offices with a silly hat on.